electrical discharge machining puzzle

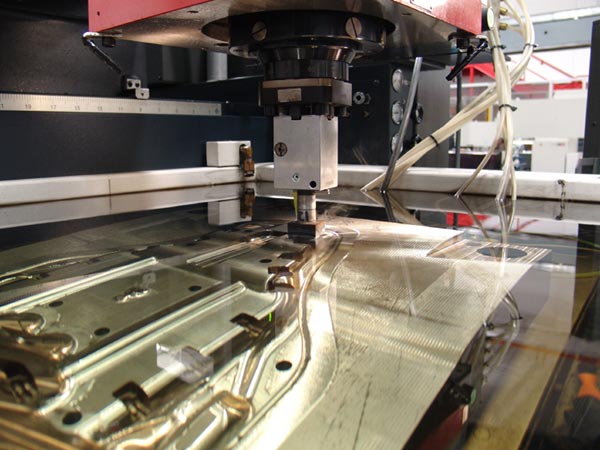

Northern Gauge has the capability to wire cut EDM pieces with 400 x 300 mm XY range and with a Z axis range of 250mm. The modern EDM process that we are familiar with was developed in the mid-20th century by Soviet researchers.

Community Challenge 12 Puzzles Closed 18 By Gg314 Contests Carbide 3d Community Site

Moondrop Anti-Stress Fidget Desk Toy.

. Small Hole EDM Drilling Small hole EDM drilling also known as fast hole EDM drilling hole popper and start hole EDM drilling uses a guided hollow electrode to drill holes by means of electrical discharge machining by eroding material from the workpiece as shown in Figure 14. What Is EDM Technology. Lets delve deep into the technology the methods the applications and the equipment that makes this intricate metal shaping method possible.

Extremely high precision CNC wire cut machine with a finish of 06 µ Ra. An electrical current passes. 12900 8900.

Additional researchers entered the field and contributed many fundamental characteristics of. Electrical discharge machining EDM also known as spark machining spark eroding burning die sinking wire burning or wire erosion is a manufacturing pr. A machining method typically used for hard metals Electrical Discharge Machining commonly known as EDM Machining makes it possible to work with metals for which traditional machining techniques are ineffective.

Machining and machine-tools 2013 Download as PDF About this page. Rated 500 out of 5. The blasts come with extremely high frequency something like 20000 sparks per second along the length of a brass wire.

The generated thermal energy leads to high temperatures which result in local melting and evaporation of workpiece material. Rated 500 out of 5 based on 7 customer ratings. 2 12 PROJECT BACKGROUND.

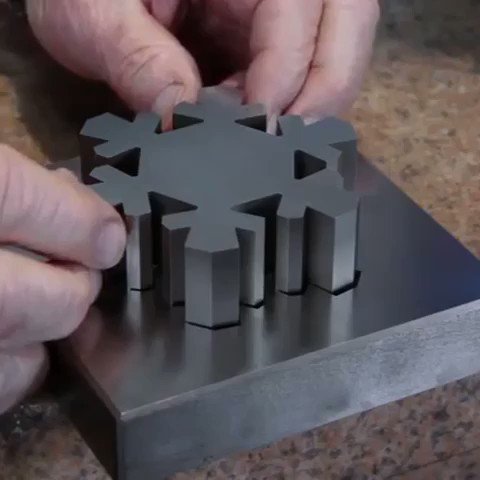

Electrical discharge machining leads to these perfectly fitted steel puzzles. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools called electrodes and the part being machined in the presence of a dielectric fluid. Known as EDM spark erosion technology Electrical Discharge Machining the manufacturing process solves the kind of machining puzzles that can stymy EDM deprived workshops.

An important point to remember with EDM Machining is that it will only work with materials that are electrically conductive. The spark generated by this process produces heat which remove metal by erosion and evaporation. Electrical Discharge Machining also referred to as EDM or EDM Machining is an ideal process in machining complex shapes and contours that cannot be handled be convention cutting technology.

Electrical discharge machining process works on the basic principle of spark generation and metal removed by spark erosion. Electrical discharge machining leads to. Crossposted by 3 years ago.

In EDM or electrical discharge machining theyre not physically touching the parttheyre machining with lightning bolts literally sparks. Wire EDM Puzzle Pieces. The most important process missing from the list is that of electric discharge machining EDM of Mercurys surface.

Electrical Discharge Machining is also called or known as Spark machining spark eroding burning die sinking wire burning or wire erosion. Understanding Electrical Discharge Machining 25 C. Electrical discharge machining EDM actually is a process of utilizing the removal phenomenon of electrical-discharge in dielectric.

The discharge generator effect used by this machine known as the Lazarenko circuit was used for many years in the construction of generators for electrical discharge. Electrical discharge machining EDM has long been the answer for high accuracy demanding machining applications where conventional metal removal is difficult or impossible. The process involves an electrical discharge.

Fundamentally the electric erosion effect is understood by the breakdown of electrode. Known by many other names including spark machining arc machining and inaccurately burning the EDM process is conceptually very simple. Not only do we have the ability to wire cut with precision but we have the metrology lab to back it up and.

7 customer reviews Experience the satisfaction of advanced wire EDM jigsaw puzzle. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. EDM spark erosion is same as electric spark which burn a small hole in a piece of metal through witch it contacts.

Electric discharge machining also known as spark erosion electro-erosion or spark machining is a process of metal removal based on the principle of erosion of metals by an interrupted electric spark discharge between the electrode tool cathode and the work anode. This spark near to 8000 to 12000º C. EDM typically works with materials that are electrically conductive although methods have also been proposed for using EDM to machine insulating ceramics.

This discharge occurs in a voltage gap between the electrode and workpiece. Therefore the electrode plays an important role which affects the material removal rate and the tool wear rate 4. Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid.

The Wiron Metal Cube creates a mesmerizing seamless effect when assembled. AbstractIn electrical discharge machining EDM the machining characteristics of the process directly depend on the discharge energy which is transformed into heat in the machining area. Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques.

This is a manufacturing operation in which we used to make desired shapes by using an electrical spark. This is how an electro-discharge machine looks like. Electrical Discharge Machining EDM is the thermal erosion process in which metal is removed by a series of recurring electrical discharges between a cutting tool acting as an electrode and a conductive workpiece in the presence of a dielectric fluid.

The problem of the astrophysics mind set can be seen in the language used the stream of hot ionized gas emitted by the Sun is better understood by plasma physicists as an equatorial solar current sheet rather.

Oh Wow Watch A Bunch Metal Shapes Created Using Electrical Discharge Machining Fit Together Seamlessly Dr Wong Emporium Of Tings Web Magazine

Electrical Discharge Machining Leads To These Perfectly Fitted Steel Puzzles R Engineeringporn

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Metmo Cube Experience Metal In Motion By Metmo Cube Kickstarter

The Precision Of Wire Edm R Oddlysatisfying

Fabrication Vacuum Technology Inc

Edm 101 Electrical Discharge Machining Basics

Zero Tolerance Machining With The Wire Edm Making A Puzzle Cube Part 2 Us Digital Youtube

World Of Engineering On Twitter Amazing Accuracy Of Electrical Discharge Machining Wire Edm Can Cut With Accuracies Of 0001 00254 Mm Worldofengineering Engineering Technology Edm Machining Source Reliableedm Youtube Https T Co

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Amazing Cube And Sphere Made By Wire Cut Edm Machine Youtube

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Amazing Cube Made By Wire Cut Edm Machine Youtube

Wire Edm Electric Discharge Machining Medical Tooling Machining Hitachi Cable America